More information

2022/11/29

2022/11/29

2022/11/29

Application of silicone oil in lubricating oil

2019/03/11

Type and Application of New Material Polyurethane Elastomer

Published:

2019/07/31

PU elastomer, also known as polyurethane rubber, is a kind of elastomer polymer material containing more carbamate groups (- NHCOO -) in the molecular chain. It is usually prepared from oligomer polyol, polyisocyanate, chain extender/cross-linking agent and a small amount of additives. It is usually prepared from oligomer polyol, polyisocyanate, chain extender/cross-linking agent and a small amount of additives. Chain extender/crosslinking agent and a small amount of auxiliary agent are prepared.

PU elastomer, also known as polyurethane rubber, is a kind of elastomer polymer material containing more carbamate groups (- NHCOO -) in the molecular chain. It is usually prepared from oligomer polyol, polyisocyanate, chain extender/cross-linking agent and a small amount of additives. It is usually prepared from oligomer polyol, polyisocyanate, chain extender/cross-linking agent and a small amount of additives. Chain extender/crosslinking agent and a small amount of auxiliary agent are prepared.

From the perspective of molecular structure, polyurethane elastomer is a kind of block polymer. Generally, it is composed of flexible long chains of oligomer polyols to form soft segments, and diisocyanate and chain extender to form hard segments. The hard segments and soft segments are alternately arranged to form repeated structural units. In addition to the urethane group, hydrogen bonds can be formed within and between the polyurethane molecules, and micro phase regions can be formed in the soft segment and the hard segment, resulting in micro phase separation. These structural characteristics make polyurethane elastomer have excellent wear resistance and toughness, and it is known as "abrasion resistant rubber".

Polyurethane elastomer has excellent comprehensive properties, and its modulus is between ordinary rubber and plastic. It has the following characteristics:

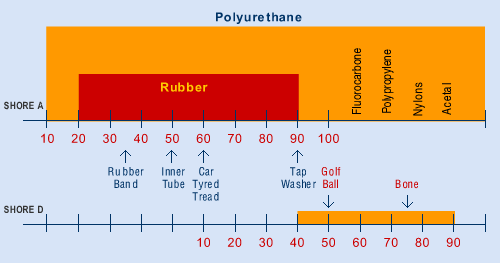

1. With high strength and elasticity, it can maintain high elasticity in a wide range of hardness (shore A) (Shore A10 ~ Shore D75);

2. Under the same hardness, the bearing capacity is higher than that of other elastomers;

3. Excellent abrasion resistance, which is 2~10 times of that of natural rubber;

4. Excellent oil and chemical resistance; Radiation resistance of aromatic polyurethane; Excellent oxygen resistance and ozone resistance; Good fatigue resistance and vibration resistance, suitable for high-frequency flexure applications;

5. High impact resistance; Good low temperature flexibility; Generally, the required low hardness can be achieved without plasticizer, so there is no problem caused by plasticizer migration;

6. Ordinary polyurethane can not be used above 100 ℃, but with special formula, it can withstand 140 ℃ high temperature; Low molding and processing costs.

Compared with metal materials, polyurethane elastomer products have the advantages of light weight, low noise, wear resistance, low processing cost and corrosion resistance; Compared with plastics, polyurethane elastomer has the advantages of non brittleness, elastic memory and wear resistance. Compared with rubber, polyurethane elastomer has the advantages of wear resistance, cutting resistance, tear resistance, high bearing capacity, transparent or translucent, ozone resistance, potting, pouring, and wide hardness range. The polyurethane elastomer has various processing methods, new technologies and new varieties are emerging, and its application prospects will be very broad.

Cast polyurethane elastomer (CPU)

Casting PU (CPU) is a kind of polyurethane elastomer produced by pouring process, pouring by liquid resin and reaction molding, which is called "pouring adhesive" for short. This kind of liquid raw material system is also called "liquid rubber". Among the polyurethane elastomer products, the casting polyurethane elastomer has the largest output and is the most important type of polyurethane elastomer at present.

1 Features

① Pouring liquid raw materials or injecting them into the product mould to react and solidify, which can directly produce thick and bulky polyurethane rubber products and products with complex shapes;

② The product has good comprehensive performance;

③ The formula composition and dosage of raw materials can be adjusted to obtain products with different hardness, and the variable range of properties is large;

④ For simple manual pouring, the equipment investment is small and the processing is convenient;

⑤ It can be used to manufacture small batch or single piece prototypes with good flexibility.

2 Categories

·TDI based polyurethane casting adhesive

(1) Polyester TDI-MOCA cast polyurethane

(2) Polyether TDI-MOCA cast polyurethane

·MDI based polyurethane casting adhesive (1) MDI-BD system polyurethane casting adhesive

(1) MDI-HQEE (HER) polyurethane pouring adhesive

·Special polyurethane casting adhesive

(1) NDI pouring glue

(2) HMDI series polyurethane casting adhesive

(3) HDI series casting polyurethane

(4) PPDI type casting polyurethane

3 Processing method

(1) Manual pouring

Manual pouring is suitable for the production of small products with small batch and many varieties. It is a common method for laboratories and small factories to produce flexible parts. Manual pouring process can be adopted for one-step method, prepolymer method or semi prepolymer method. Manual pouring is simple and flexible, and the cost is low. However, there is an uneven mixing problem, and bubbles are not easy to eliminate.

(2) Mechanical pouring

The pouring machine is equipped with an automatic metering pump and mixer. After degassing the prepolymer, it is delivered to the mixer together with the chain extender that has been strictly measured for uniform mixing. During pouring, the liquid material is injected into the mold through the gate of the mixer, and the product is obtained after vulcanization. The mixer can operate continuously or intermittently. The mixing and injection actions can be carried out simultaneously. Mechanical pouring can be carried out continuously and intermittently, with high production efficiency and stable product quality. It is suitable for the production of large batches and medium and large products.

(3) Special pouring process

The production of castable polyurethane elastomer can generally adopt normal pressure pouring, that is, the reaction mixture is poured into the open mold and then closed. In the process of normal pressure pouring, it is easy to mix the air brought in by stirring, which may cause bubbles in the elastomer products. For some products with complex shapes or where bubbles are not allowed in the glue, the mold can be placed in a large vacuum chamber. The mold can be injected by pouring pressure, and the mold can be vacuumed while pouring. This method is called vacuum pouring.

There are vertical pouring method, inclined pouring method, centrifugal pouring method, rotary pouring method and so on to inject liquid rubber into the mold. Proper methods must be adopted to avoid mixing bubbles during injection.

Thermoplastic polyurethane elastomer (TPU)

Thermoplastic polyurethane elastomer (TPU for short), also known as PU thermoplastic, is a linear block copolymer composed of oligomeric polyol soft segment and diisocyanate chain extender hard segment.

TPU accounts for about 25% of the total amount of polyurethane elastomer, and its main uses include: automobile parts and machine parts, sports soles, rubber rollers, wires and cables, hoses, films and sheets, fabrics (coatings and high elastic clothing and socks, etc.), tape adhesives, fabric coatings, adhesives, etc. TPU can be divided into polyester type and polyether type according to soft segment structure. According to the classification of structural characteristics, it can be divided into full thermoplastics and semi thermoplastics.

TPU is usually granular with good reprocessing property. Thermoplastic processing methods, such as extrusion, injection, calendering, molding, etc., can be used to plasticize TPU particles at higher temperatures to make products or composite products of various shapes. Extrusion molding and injection molding are the most widely used, accounting for more than 70%. TPU is also used to manufacture elastic fibers, synthetic leather resins, adhesives and coatings.

Mixed polyurethane elastomer (MPU)

Mixed polyurethane elastomer (MPU) is the earliest type of elastomer developed. Its main processing characteristic is to first synthesize solid raw rubber with stable storage, and then process it with general rubber mixing machine to obtain thermosetting polyurethane elastomer with network molecular structure. According to the soft segment structure of the main chain, the mixed polyurethane can be divided into polyester type and polyether type, which can be divided into S vulcanizate and DCP vulcanizate according to different vulcanizing agents.

The main characteristics of mixed polyurethane elastomer are as follows:

① General rubber processing equipment can be used to produce products;

② Compared with general rubber, it has good wear resistance, high tear strength, small compression permanent deformation and good oil resistance.

③ The relative molecular weight of mixed polyurethane elastomer is generally higher than that of cast polyurethane elastomer, ranging from 10000 to 30000. Raw rubber with different Mooney viscosity can be obtained by selecting different raw material ratios.

④ Fillers such as carbon black and white carbon black can be added to the mixed polyurethane elastomer to improve the hardness and reinforcement of the products.

Application of Polyurethane Elastomer

1. Application in coal preparation, mining, metallurgy and other industries

Polyurethane elastomer is a non-metallic material that most meets the requirements of mines and can replace some metal materials. Polyurethane elastomer products used in mines include sieve plate, elastomer lining, conveyor belt, etc. Polyurethane rubber sieve plates include relaxation sieve plates, tension sieve plates, slit sieve plates, etc. The polyurethane rubber sieve plate has excellent wear resistance, water resistance, oil resistance, vibration absorption and noise elimination, high strength, strong adhesion with the metal framework, low noise, good self-cleaning effect, and reduces the load of the sieve machine, saves energy, extends the service life of the sieve machine, and has high screening quality.

Many mining equipment, such as shaking table, flotation machine, special concentrator, flow family, spiral launder, crusher, magnetic separator, pipeline and elbow, need wear-resistant lining when contacting with crushed stone and other materials; Polyurethane elastomer is the preferred material for steel core polyurethane drive wheel of mining monorail crane, flame retardant and anti-static polyurethane conveyor belt, equipment cable TPU sheath, dust ring, shock absorber, etc.

2 Application of polyurethane cots

Polyurethane top roller is a kind of polyurethane rubber products with excellent performance, which is generally made by casting process to cover steel or iron roller with a layer of polyurethane elastomer. According to their uses, they can be classified into: husking cots for grain processing, squeezing cots and sizing cots for paper making industry, wire drawing rolls, drafting rolls and cutting rolls for textile industry, transmission bearing cots for wood, glass and packaging industries, various cots for printing and dyeing machinery, small cots for various instruments, transmission cots for conveying systems, printing cots, transmission cots for metal cold rolling, color coated cots for metal steel plates, etc, The rubber layer of these cots can be made of polyurethane elastomer.

Most rubber cots are made by casting process, and generally, the steel core is placed in the center of the cylindrical mold to cast the elastomer for molding. Centrifugal pouring method or rotary pouring method can be used for special cots. The rotary casting method does not need a mold, and the room temperature vulcanized casting elastomer system is used, so the total processing time is shortened.

3 Polyurethane rubber wheel and tire

Polyurethane elastomer has large bearing capacity, wear resistance and oil resistance, and is firmly bonded with the metal framework. It can be used to manufacture rubber wheels widely used in various transmission mechanisms, such as; Supporting pulley, guide pulley and pulley of cable car for production line conveyor belt. In terms of sports and entertainment, the roller skates and skateboard wheels of high-end skates are made of polyurethane. The polyurethane rubber wheel also has the characteristics of oil resistance, good toughness, strong adhesion, etc. It is very effective in the use of mining monorail cranes, gear rail cars, cleaning cars and other vehicles. Polyurethane is also used for transmission wheels of very small electronic and precision instruments, various universal wheels, etc.

There are also micro foam tires, PU foam filled tires, etc.

4 Mechanical accessories

Various sealing rings, damping blocks, couplings, automobile anti-skid chains, etc.

5 Die lining and blanking template for sheet metal parts forming

When blanking thin sheet parts with conventional steel dies, there are often burrs on the fracture surface. The stamping technology of using polyurethane rubber to replace traditional steel die is a leap in sheet metal stamping technology. It can greatly shorten the mold manufacturing cycle, extend the service life of the mold, reduce the production cost of the formed parts, and improve the surface quality and dimensional accuracy of the parts. It is especially suitable for the trial production of small and medium-sized batch and single piece products, and is more suitable for thin and complex stamping parts.

In the ceramic tile and ceramic production line, the use of PU elastic inner lining mold can reduce production costs, improve production efficiency and yield. Polyurethane can be used to make concrete molds, polyurethane molds can reproduce various patterns, and decorative blocks can be produced. Polyurethane elastomer rods, tubes, and plate pads are used to replace metal springs as buffer components in the stamping production of hardware molds, with high elasticity, flexibility, high original shrinkage deformation strength, and no damage to the molds.

6 Shoes

Polyurethane elastomer has the characteristics of good cushioning performance, light weight, wear resistance, skid resistance, and good processing performance. It has become an important synthetic material for shoes in the shoemaking industry. It can be used to manufacture sports shoes, soles, heels, and toe caps for baseball shoes, golf balls, soccer, as well as ski shoes, safety shoes, and leisure shoes. The polyurethane materials used for shoe materials include cast microporous elastomer and thermoplastic polyurethane elastomer, mainly microporous elastomer soles.

Polyurethane microporous elasticity is light in weight and good in wear resistance, which is widely recognized by shoe manufacturers. The product density is low, much lighter than traditional rubber soles and PVC shoe materials. In China, microporous polyurethane elastomer is mainly used for soles and insoles of tourism shoes, leather shoes, sports shoes, sandals, etc. In foreign countries, it is mainly used for soles of special sports shoes requiring wear resistance and elasticity, with diversified designs. TPU heel has high wear resistance. Thermal decomposable foaming agent can be added into injection molding to make foamed TPU elastic shoe material.

keywords

Contact Us

Nantong San Ying Polyurethane Co., Ltd.

Address:8th floor, Hurunxingcheng, No. 555 Haiyang North Road, Chengbei Street, Rugao City, Jiangsu Province, China.

Tel:+86-513-87691698

Mobile:+86-18962773679

Fax:+86-513-88560029

Email: jane@sanychem.com

Products

Follow us

Copyright © 2022 Nantong San Ying Polyurethane Co., Ltd.