More information

2022/11/29

2022/11/29

2022/11/29

Application of silicone oil in lubricating oil

2019/03/11

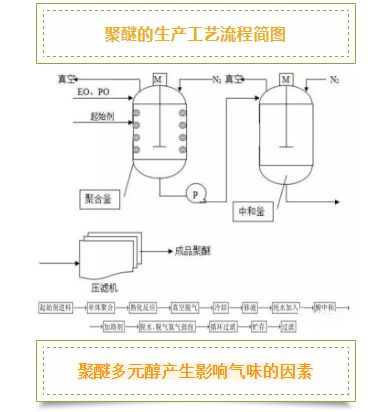

Analysis of Factors Affecting Odor of Polyether Polyol

Published:

2019/07/01

Polyether polyol is an important polymer material, which is mainly used to make various polyurethane materials. According to their different functionality, relative molecular weight and molecular structure, polyether polyols are generally divided into soft foam polyether, hard foam polyether, CASE polyether (i.e. polyether for coating, adhesive, sealant and elastomer) and POP (polymer polyether polyol) series. In recent years, with the continuous improvement of the production process, the quality of products is also improving, but the odor problem of polyether products has not been solved very well, especially the soft foam polyether polyols used in furniture, automobile, clothing and other industries,

polyether

Polyether polyol is an important polymer material, which is mainly used to make various polyurethane materials. According to their different functionality, relative molecular weight and molecular structure, polyether polyols are generally divided into soft foam polyether, hard foam polyether, CASE polyether (i.e. polyether for coating, adhesive, sealant and elastomer) and POP (polymer polyether polyol) series. In recent years, with the continuous improvement of production technology, the quality of products is also improving, but the odor problem of polyether products has not been solved very well, especially the soft foam polyether polyols used in furniture, automobile, clothing and other industries, which are directly related to people's daily life, and the odor problem is particularly prominent. The smell problem is particularly prominent.

Theoretically, the odor of polyether polyol is mainly produced by low molecular aldehydes, alcohols and carboxylic acids, but there is no specific standard for the odor itself, which is difficult to measure with data. Even with the help of advanced detection instruments, the odor of polyether polyol can not be completely defined, and it can only be determined based on human experience. We must rely on people's experience to make a decision. can

Note: Scoring standard: 1 point - severe taste; 2 points - heavy taste; 3 points - a little taste; 4 points - slight taste; 5 points - tasteless.

1Effect of System Vacuum on Odor of Polyether

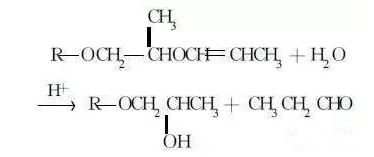

In the neutralization process of the end alkenyl polyether in the crude polyether, the polyether decomposes into aldehyde, and the decomposition reaction is shown in the following formula:

At the same time, there are unreacted propylene oxide monomer, oligomer and water in the crude polyether. The low volatile matter must be removed by vacuum, and the degassing process under nitrogen gas flow (commonly known as nitrogen bubbling) will achieve better results. However, if the vacuum capacity can not reach the conditions to remove the low boiling point substances, it is bound to affect the odor of polyether products. Therefore, the minimum pressure of the current device is monitored in the experiment. It can be seen from the monitoring that the pressure of the current device can reach below 0.004 MPa. Therefore, it is stipulated in the production that after the system pressure is lower than 0.004 MPa in the vacuum process, continue to vacuum for 1 hour, and then vacuum degassing under nitrogen flow for more than 5 hours. At the same time, the nitrogen flow is stably controlled at 20~30 m3/h to ensure that the low boiling point substances in polyether products are completely removed.

2Effect of Storage Temperature on Odor of Polyether

Through the comparison of the reserved samples, it is found that the odor of the products on the production line is obviously lower than that of the products in the storage tank. To find out the reason, the experiment first compares the odor of polyether under different storage temperatures. Compared with the storage of polyether at 110~10 ℃, it is found that the smell of polyether decreases with the decrease of storage temperature, but the stored materials are cooled to below 50 ℃, and the smell of polyether does not change significantly with the extension of time. Therefore, it is stipulated that the materials should be cooled to below 50 ℃ after passing the cycle filtration, and then transferred to the storage tank for storage.

3Effect of Filter Temperature on Polyether Odor

Through field investigation, it is found that when the filter is purged before circulating filtration, it will carry a large amount of pungent gas, and its smell is very similar to that generated by polyether. The reason for the smell is analyzed, which is mainly due to the partial overheating of the equipment during heating, leading to the oxidative decomposition of polyether. Therefore, in order to ensure that the wall of the superheated kettle will not be contacted during the material circulation filtration, it is stipulated in the production that the steam manual valve must be closed before and after the use of the neutralization kettle, filter and other equipment.

4Effect of Phenol/Amine Antioxidants on Odor of Polyether

Antioxidants are often added in the production of soft foam polyether polyols to prevent the oxidation of polyethers. Generally, BHT (2,6-di-tert-butyl-p-methylphenol) and TSSH-1 composite antioxidant are added. By comparing the sample of blank polyether without antioxidant with the sample of polyether with antioxidant, it is found that the smell of blank sample is lower, and the smell of sample increases significantly after adding antioxidant. Through understanding the latest antioxidant technology and comparing the antioxidants, it is found that the antioxidant system used at this stage has a strong smell, and the improvement of the properties of the products such as core burning resistance, light stability, anti fumigation, and anti fabric pollution cannot meet the environmental requirements of high-grade polyurethane products (such as pillows, shoulder pads, car cushions, etc.). In order to ensure that the polyether products reach the ideal low odor and high quality state, the antioxidant system must be replaced.

5Effect of Polymerization Temperature on Odor of Polyether

By comparing the odor of polyether products at different temperatures on the production line, it was found that the odor of two batches of polyether products with polymerization temperature over 120 ℃ was significantly higher than that of polyether products produced at the same time. When the polymerization temperature is reduced by 5 ℃ and 10 ℃ respectively, the odor of the product will be reduced, but when the polymerization temperature is higher than 10 ℃, the polymerization reaction speed will be slower and the production efficiency will be affected. So the optimum polymerization temperature was 115 ℃.

6Effect of Neutralization Process on Odor of Polyether

In the original neutralization process, water was added first, and then 85% concentrated acid was added after liquid transfer. In this process, the by-products increase due to the contact between local concentrated acid and crude polyether, which also affects the odor of polyether to some extent. In order to improve the uniformity of the acid-base neutralization reaction and reduce the generation of by-products, it is now changed to mix water and acid in the drying kettle, dilute the acid and then use it for neutralization, and reduce the neutralization temperature from 90 ℃ to 80 ℃. Under the condition of lower temperature and lower acid concentration, the by-products generated by acid and polyether can be avoided or reduced.

7Effect of the Quality of Polymeric Monomer Propylene Oxide on the Odor of Polyether

The aldehyde value and water content of imported propylene oxide (PO) are about 80% and 70% lower than those of domestic PO. The product quality is good, while the quality of domestic PO is poor. Three batches of soft foam polyether polyols were produced with domestic PO and imported PO respectively in the experiment. Through sampling and comparison, the polyether produced with imported PO was better than that produced with domestic PO in terms of smell. And the odor of polyether produced in different batches is also different. Therefore, the quality of the polymerization monomer PO also has a certain impact on the generation of polyether odor.

8Influence of equipment airtight stability on polyether odor

During the operation of the equipment, due to vibration, wear and other reasons, "leakage points" may occur at any time, resulting in poor airtightness stability of the reactor, resulting in fluctuations in product odor. In order to find and deal with the "leakage point" of the equipment in time, it should be stipulated in the production that every batch of products should be comprehensively inspected for the interface, exhaust valve, level gauge, mixing, etc. of the equipment before drying, and the "leakage point" should be dealt with in time. At the same time, in order to ensure the stability of the equipment, the airtightness of the reaction kettle, drying kettle, vacuum system, etc. shall be inspected by using the intermittent production.

keywords

Contact Us

Nantong San Ying Polyurethane Co., Ltd.

Address:8th floor, Hurunxingcheng, No. 555 Haiyang North Road, Chengbei Street, Rugao City, Jiangsu Province, China.

Tel:+86-513-87691698

Mobile:+86-18962773679

Fax:+86-513-88560029

Email: jane@sanychem.com

Products

Follow us

Copyright © 2022 Nantong San Ying Polyurethane Co., Ltd.